Back to overview

Turnkey systems for textile processing

Workflow for processing textiles

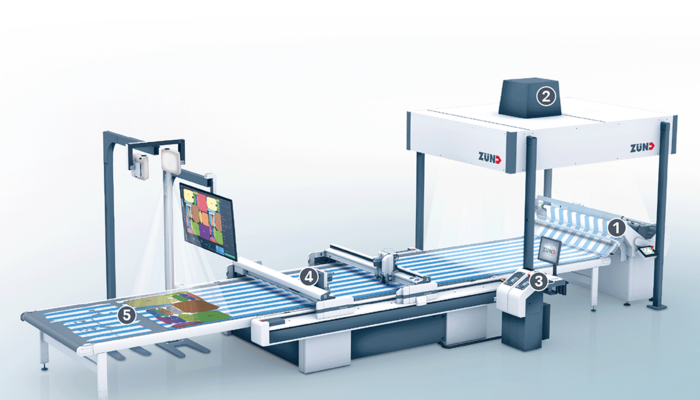

- Load

Zünd offers a wide range of material-handling systems. They automate material-feeding and ensure tension-free andvancing. - Capture

A camera captures the fabric that needs to be processed and its exact position and dimensions, no matter whether the material is plain, printed, or patterned. - Create marker

Powerful nesting software places parts on the fabric as tightly as possible to maximize material yield and automatically creates the marker. - Cut

Textiles are cut to shape with high-performance tools. The vacuum system provides reliable hold-down during the cutting process. - Unload

For efficient removal, cut parts need to be identified quickly and unmistakably. The system automatically color codes and projects other relevant data to help the operator with picking/sorting.

Digitally printed sportswear

Flexible and precise: processing custom-printed textiles

Digitally printed custom fabrics are the latest trend. Zünd's Print&Cut workflow provides the necessary data consistency. Because of their open interface, Zünd cutters can be easily integrated in existing workflows and enable efficient cutting of custom-printed textiles using register marks for matching cut to print.

Apparel

Perfect pattern matching on patterned fabric

Whether dotted, checkered, or striped - advanced registration systems are capable of recognizing patterns automatically and reliably. In seconds, markers are perfectly matched and adjusted to the pattern at hand.