Foams4Sports Invests

Foams4Sports, a leading manufacturer of sports safety padding, has invested in the state-of-the-art Zünd G3 XL-3200 to boost product stock levels and reduce lead times. Based in Ashton-Under-Lyne, Lancashire, Foam 4 Sports has been supplying high-quality sports equipment to the NHS, martial arts clubs, prisons, school halls, and outdoor sports venues for over 40 years.

Ben Michael, General Manager at Foams4Sports Ltd, told us, “While we offer a wide range of standard products, such as gymnastics mats, crash mats, and wall padding, we also provide a fully bespoke design, manufacture, and installation service for padding suitable for various environments.”

As proud members of the Sports and Fitness Equipment Association, and a leading manufacturer of sports and safety padding. Ben said “Our manufacturing process of our mats and padded products is supported by a team of experts who can advise on the recommended foam density, thickness, PVC covering and wear sheets required for the purpose. We can then measure up and produce accurate CAD drawings in order to deliver a bespoke manufacturing and installation service.”

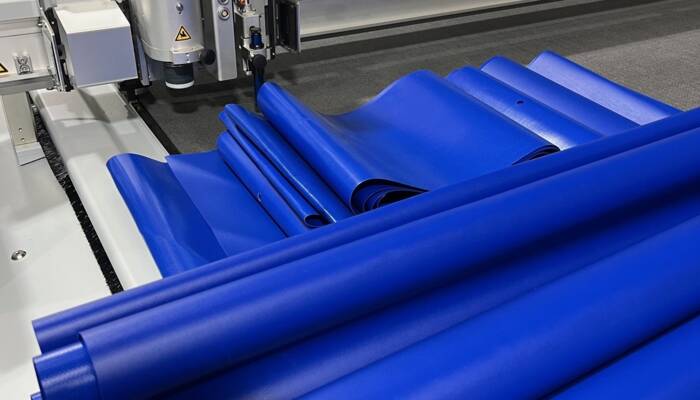

In late 2023, Foams4Sports reevaluated their manufacturing process, which included hand-cutting PVC and foam parts for martial arts, gymnastics, pole dancing, parkour, and other impact sports mats. Ben explained, “Our lead times are among the shortest in the market, but we are always looking for manufacturing improvements. Recognising the need for growth, we transitioned from traditional hand-cutting to digital cutting methods, leveraging Zünd Cutting Technology for efficiency and precision.”

Although aware of the various digital cutting technologies available, they held off deciding on the actual machine until the appointment of Ben Michael as General Manager. Recognising the imperative aspiration for growth, Ben led the transition from traditional hand-cutting to state-of-the-art digital cutting methods, particularly leveraging his familiarity with Zünd Cutting Technology. He emphasised, "To sustain efficiency, precision, and minimise material waste, we needed to pivot towards digitalisation."

Ben visited Zund UK, where he received an in-depth product demonstration and explored workflow solutions tailored to address their business challenges. Impressed by the expertise and professionalism exhibited by the Zund UK team, Ben was convinced of the partnership's potential. Subsequently, with full support from all stakeholders, Foam 4 Sports invested in a Zünd G3 XL-3200, welcoming the new addition to their facility in March 2024.

Reflecting on the transformative investment, Ben said, " Our new Zünd machine will change the way we manufacture by offering precision, efficiency, and versatility. With its comprehensive technology, the Zund enables us to streamline our production processes, accelerate turnaround times, and deliver exceptional quality products to our customers.”