L3 Leather Cutter

Smart, efficient leather cutting: The L3 is perfect for the leather industry and is specifically designed for producing top-quality leather goods.

Produce high-quality leather goods

Take your productivity in leather manufacturing to the next level. Process leather, sole, lining, and stencil materials precisely and efficiently with the L3. The cutting system handles even highly complex patterns at exceptionally high speeds. Furthermore, because of its superior precision, time-consuming post-production finishing tasks have become a thing of the past.

L3 cutter overview

The 2 different cutter models of the L3 line let you select the perfect machine size for all your production needs. Our digital cutting systems are intelligent, efficient, and ready for the future.

Process leather, sole, lining, and stencil materials precisely and efficiently with the L3 cutting system. With the right tool, you can cut leather at speeds of up to one meter/40 in per second. With the L3 you can produce leather goods economically, efficiently, and at premium quality levels.

Couches and sectionals, office chairs, car seats, leather steering wheels - Zünd cutting systems are specifically designed for producing top-quality leather goods. Many well-known manufacturers in the leather industry rely on Zünd cutting systems. This is not surprising considering the outstanding performance, low cost of ownership, and easy integration into your workflow ensuring a rapid ROI. At 3240 x 1000 mm /128 x 40 in, the working area of this high-performance leather cutter is perfect for efficiently processing animal hides.

Zünd cutting systems are used both in prototyping and production. We can offer you the right solution for your production environment, tailored to your individual needs. With a large variety of tools and a range of sophisticated material-handling solutions, we can guarantee a perfect fit.

The L3 cutter is designed for non-stop operation with loading/unloading and cutting all taking place at the same time. The machine can be set up for two types of production workflows and material handling: With the standard set-up, the entire working area is available for processing once the material is loaded/unloaded; in a tandem set-up, the working area is split into two halves, making it possible to load and unload materials while the machine continues cutting. A green LED strip indicates in which area production has ended and new material can safely be loaded or unloaded.

L3 cutter sizes

Choose from 2 different sizes to select the perfect machine for your application.

Zünd L3 – efficient, robust, powerful

The L3 is extremely fast and robust and gives manufacturers the ability to dramatically increase their output. The exceptional productivity of the cutter stems from its smart motion control, precise drive system, and fine-tuned cutting technology. Furthermore, with its superior precision, the cutter proves itself by immediately processing even highly complex patterns at exceptionally high speeds.

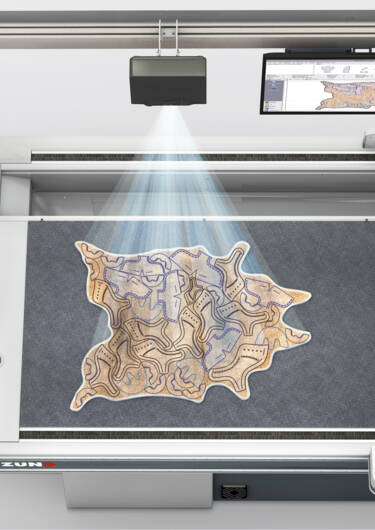

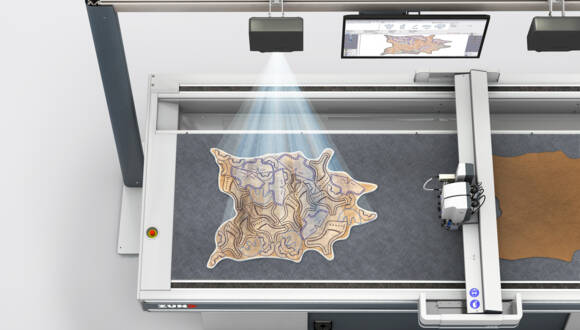

A projection system visually supports the operator throughout all phases of production - from capturing the leather to nesting and removing cut parts.

Energy-efficient vacuum turbines ensure reliable material hold-down during the cutting process. The leather is held down and processed on a highly stable aluminum cutting surface, which is divided into 56 individually controllable vacuum zones. Adjustable vacuum generators with a power of up to 12 kW create the necessary vacuum. The quality and design of the table plate guarantee optimal hold-down and reliably clean, precise cuts.

You have the flexibility to precisely choose and combine the tools you need for the job at hand and in accordance with your specific production requirements. You can equip the L3 with up to seven different tools.

Fast, precise, efficient: the setup of cutting tools, blades, and bits occurs fully automatically with an integrated tool calibration system. The ITI Initialization System makes the process quick and precise and eliminates any manual steps in determining the proper cutting depth.

The L3 working surface is slanted, which facilitates the loading/unloading process. For optimal accessibility, the control panel is mounted on a guide rail and can be freely moved.

Adaptable high-performance modules

Find the perfect module / tool for every application.

Suitable for fabric and technical textiles. The driven rotary blade allows for very high processing speeds.

The Driven Rotary Tool is designed for cutting all manner of textiles reliably and economically. The material is cut with a motor-driven ten-segmented blade. The blade geometry reduces the drag force on the material considerably and also helps cleanly sever thread or fiber. This processing method produces clean, precise cuts even on very loose, coarsely knit materials.

Choice of two RPM setting depending on the application. Also suitable for cutting materials with low melting points.

- Use of rotary blades reduces drag on the material

- Choice of 2 RPM settings (20,000/12,000 rpm)

- Clean separation of each thread or fiber

- Compatible with G3, S3, D3, L3

Cutting tool with high oscillation frequency for soft to medium-density materials.

The Electric Oscillating Tool is suitable for cutting soft to medium-density materials. The high oscillating frequency enables high processing speed and efficient throughput.

Depending on the application, the EOT is available with 0.5 mm or 1.0 mm stroke. To accommodate different substrates and levels of detail, Zünd offers a wide range of both flat and pointed oscillating blades.

- Depending on application, available with 0.5 mm or 1.0 mm stroke

- Perfect for cutting detailed contours

- Very high stroke frequency

- High processing speeds

- Compatible with G3, S3, D3, L3

Powerful tool with high-performance electric motor for processing thick cardboard and leather.

The Electric Oscillating Tool is ideal for efficiently processing materials such as honeycomb display board, thick cardboard, and tough leather. This high-performance tool is equipped with a powerful air-cooled motor. With an extended, 2.5 mm stroke andhigh oscillating frequency, the EOT-250 is capable of processing challenging materials at very high speeds. Zünd offers a wide variety of high-quality blades for use with the EOT-250.

- 2.5 mm stroke

- Very high processing speeds

- Wide range of Zünd oscillating blades available

- Compatible with G3, S3, D3, L3

Used for marking and labeling a wide range of materials with commonly available pen inserts/cartridges.

Zünd marking modules accommodate a variety of pen and ink inserts. Typical applications include plotting die-lines with ink on polyester film, marking seams on leather with water-soluble silver pens, and labeling parts or patterns with ballpoint pen. The Marker Module is compatible with all drawing/plotting Inserts available from Zünd.

- Simple handling

- Plotting/drawing of die-lines, seams, patterns, guidelines

- Wide assortment of cost-effective drawing tools available from Zünd

MAM-S (G3, D3)

MAM-D (G3, D3)

MAM-SE (S3)

MAM-SP (S3)

MAM-SPS (S3, L3)

MAM-SPD (S3, L3)

Flexible in the choice of materials

Downloads

Questions?

Contact us for more information, for scheduling a demonstration, and for anything else you might like to know about digital cutting.