Q-Line with BHS180

The Q-Line with BHS180 raises the bar for industrial, pallet-to-pallet production.

Flexible, cost-efficient, and fully automated production – ideally without the need for dies.

Do you work with printed or unprinted sheet materials like corrugated board, cardboard, or honeycomb board and recognize one or more of these challenges?

If you’re reaching the limits of your current production process, looking to automate, and aiming to be ready for the future of industrial pallet-to-pallet production, then watch the full video.

With the Q-Line, you can overcome these hurdles and turn them into a competitive advantage, staying one step ahead of the competition.

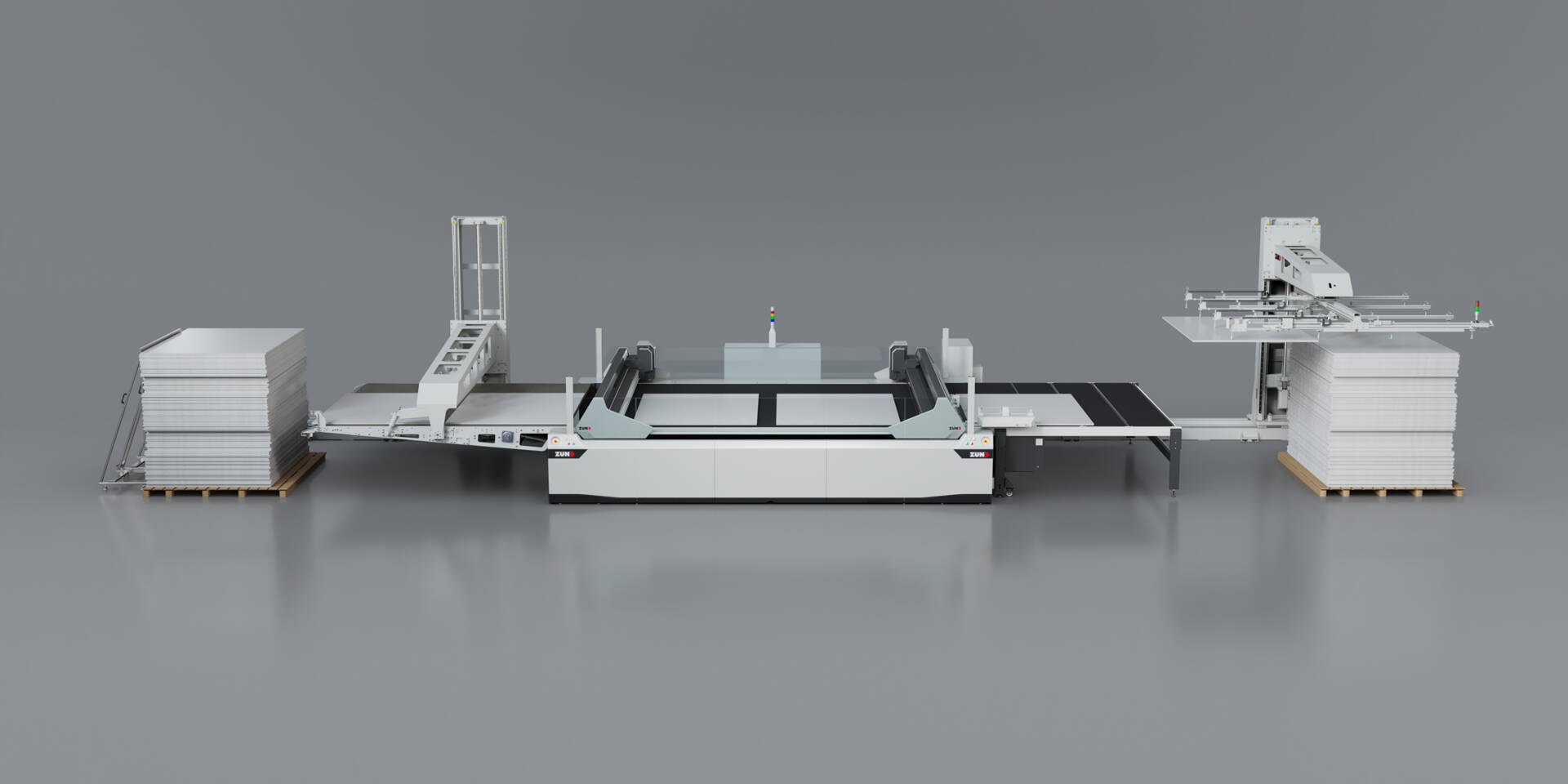

Q-Line with Board Handling System – BHS180

The new Q-Line with board handling system – BHS180 and UNDERCAM is a comprehensive system solution. It is specifically tailored to the requirements of highly automated, industrial finishing in the digital production of displays and printed packaging. This new system makes it easier than ever for display and packaging manufacturers to optimize their production processes and increase their efficiency.

The individual components of this digital production solution, i.e. the board feeder with UNDERCAM, Q-Line cutter, and off-load unit, are perfectly coordinated to enable next-level productivity. Together, they offer the user highly stable and reliable cutting and thus efficient, economical processing of printed board material.

Q-Line with BHS180

The Q-Line with BHS180 is a comprehensive, advanced system solution you can rely on to take your production to the next level.

Perfectly coordinated

The Q-Line with BHS180 offers exceptional performance for every packaging and display manufacturer. Whether the BHS180, UNDERCAM, or Q-Line – each component of this digital cutting solution is packed with exciting new features. In combination, they guarantee uninterrupted, unattended production, providing users with an enormous potential for savings, irrespective of company size. The bottom line: an investment with exceptionally high value retention.

The machine concept behind the Q-Line with BHS180 is redefining performance. Machine components, such as the solid, mineral-cast substructure, the linear drive, and beams made of carbon fiber-reinforced plastics work together to provide impressive machine speeds of up to 2.8 m/s.

Unprecedented performance also manifests itself, among other things, in an impressive acceleration of up to 2.1g, which enables extremely high processing speeds and significantly shorter cycle times per job.

Q-Line cutters are a force to be reckoned with. Based on the latest technology, the tool modules are capable of exerting a creasing pressure of up to 500 N.

Increase the productivity and efficiency

Increase the productivity and efficiency of your finishing processes with Q-Line and BHS180— we will help you do it!

Simply smart

The Q-Line with BHS180 is an all-in-one solution. In addition to the hardware, it also comprises a comprehensive set of services, intuitive and straightforward software, as well as a wide range of consumables. Everything has been developed specifically to increase machine performance and productivity and decrease setup times. And first and foremost, it has been developed and tested for outstanding cutting results at maximum speeds.

The Q-Line

Cutter sizes

The Q-Line with BHS180 is available in three sizes. Choose the machine size best suited for your specific requirements—it makes no difference whether you are producing one-offs, short or long runs.

Material handling

Increase your productivity and eliminate downtime with fully automated material transport from pallet to pallet. Operator intervention is reduced to a minimum. The Q-Line with BHS180 removes bottlenecks associated with manual material handling in your production workflow.

Custom order processing, from one-offs to medium runs, requires a seamless and transparent flow of data. Using QR codes, the system captures the embedded data associated with each job and thus ensures intelligent, error-free QR-code-based production. It allows processing different jobs within a stack, and production of each individual job can begin automatically.

The UNDERCAM integrated in the board feeder captures the precise location of the graphics printed on the board. It reliably detects any distortions in the print and perfectly matches the cut to the print every time. With every scan, the software adjusts the cut paths to the printed image, on the fly and in real time, significantly reducing the cycle time for each job.

Sensors on the board feeder identify the material edges for proper alignment. If the board is not within tolerance, the board feeder grabs it once more and realigns it so that it can be fed onto the cutter without interruption. This allows even imperfectly stacked materials to be processed, which further streamlines the production workflow.

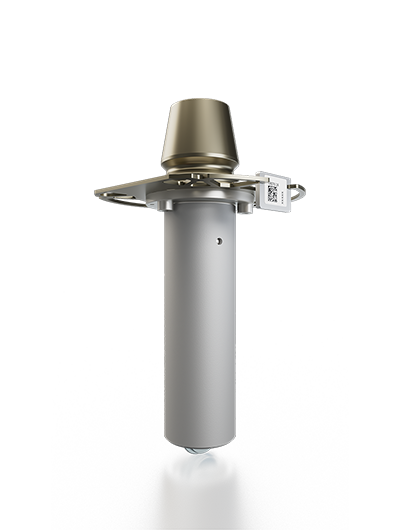

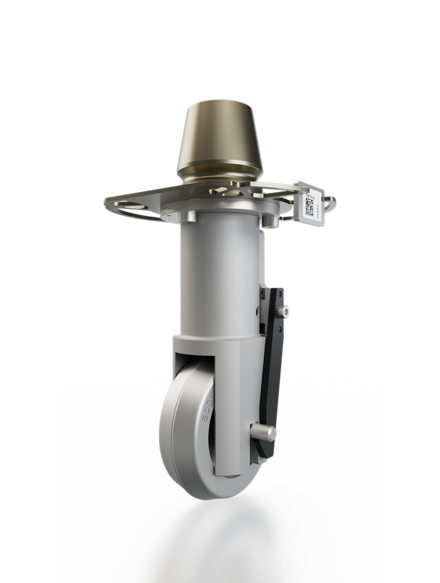

To ensure reliable board and sheet separation during the loading process, redeveloped suction cups can be individually adjusted for different materials via Zünd Cut Center – ZCC.

The innovative design of the off-load system allows bridge-free cut boards to be stacked easily and reliably, making it easier to handle completed jobs in the stack. Different jobs are stacked slightly offset, which speeds up the subsequent job separation by the operator. Any faulty boards are also set aside with an offset and are therefore easy to spot as the pallet is removed.

Digital tool management

The Q-Line with BHS180 tool management makes digital finishing more efficient than ever before. The Tomac Tool Management Client takes care of tool management to ensure easy and, above all, automated processes. Tool management digitally links the tool with presets, which also saves valuable time in setup and tool changes.

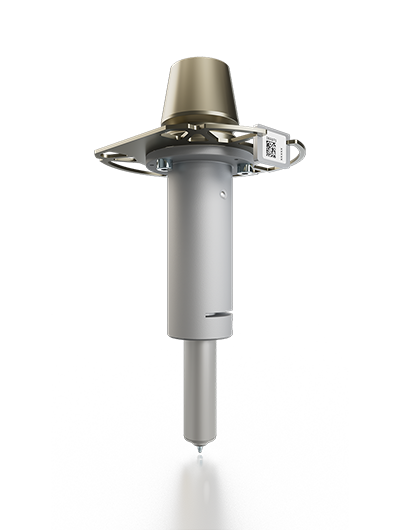

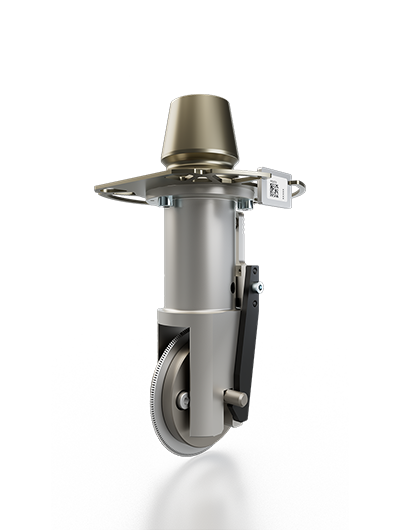

The Q-Line with BHS180 comes standard with three tool modules. Speed is of the essence for the two AUTOMO E modules, whereas AUTOMO L is all about force, producing a pressure of up to 50 kg. This makes it the obvious solution for creasing with large crease wheels such as CRETO 150. The third module, INCAM, is the sensor module. It captures registration marks, QR codes, and detects material edges.

AUTOMO is compatible with a wide range of tools.

AUTOMO is compatible with a wide range of tools. To best meet different application requirements, the modules are available in two versions.

AUTOMO serves as a carrier module for many different tools. Compatible Zünd tools can be used in a wide range of applications and require different properties.

The AUTOMO E carrier module features the latest drive technology for maximum acceleration and processing speed. The AUTOMO E offers excellent downward pressure of up to 20 kg/44 lbs.

- Mass: 5,8 kg | 12,8 lbs

- Adjustable clamping force: up to 20 kg

- Lift speed: 500 mm/s | 20 in/s

- Z acceleration: 10 m/s2 | 33 ft/s2

- Pneumatic clamping system (tool fixing), automated picking/replacing of tools from the tool magazine

- Compatible with Q-Line

The AUTOMO L is the carrier module for large tools such as the CRETO 150 but can also hold all other tools from the latest generation. The newly developed motor drive can produce a downward pressure of up to 50 kg /110 lbs.

- Mass: 7,2 kg | 15,9 lbs

- Adjustable clamping force: up to 50 kg

- Lift speed: 300 mm/s | 12 in/s

- Z acceleration: 10 m/s2 | 33 ft/s2

- Pneumatic clamping system (tool fixing), automated picking/replacing of tools from the tool magazine

- Compatible with Q-Line

The UNITO allows you to process many different materials precisely and efficiently.

The Universal Cutting Tool is capable of processing (via Thru Cut) many different types of materials precisely and efficiently.

The UNITO is a very versatile tool for cutting with drag knives. It is excellent for through-cutting a wide variety of materials. The use of drag knives enables very high processing speeds.

- One tool, two processing methods - through-cutting and scoring

- Accommodates centered drag knives UNITO C-6 (0.63 mm) and UNITO C-15 (1.5 mm)

- Accommodates off-centered drag knives UNITO E-6 (0.63 mm) and UNITO E-15 (1.5 mm)

DRAWTO is a cost-effective tool for precise marking and drawing.

DRAWTO is a cost-effective tool for precise marking and drawing on textiles, leather, rubber, or Teflon.

The DRAWTO is a drawing and marking tool. You can use the DRAWTO to easily add assembly markers, dash symbols, or lettering to different materials. DRAWTO accommodates standard drawing tools and cartridges, like ballpoint pen refills or felt-tip pens in different thicknesses.

It is mainly used to produce patterns in the textile and leather industries.

- Accommodates ballpoint-pen cartridges/refills

- Easy cartridge replacement/changes

The ELOSTO is a universal cutting tool for processing many different materials.

The ELOSTO is designed for oscillating cutting. The powerful, aircooled electric drive is able to reach very high RPM levels, ensuring maximum cutting speeds and therefore incredibly efficient cutting. ELOSTO is available with a 0.5 mm, 1 mm, 2.5 mm or 5 mm stroke depending on the application.

- ELOSTO 5

Knife stroke 0.5 mm - ELOSTO 10

Knife stroke 1.0 mm - ELOSTO 25

Knife stroke 2.5 mm - ELOSTO 50

Knife stroke 5.0 mm - Accommodates oscillating blades with thicknesses of 0.63 and 1.5 mm

- Powerful electric drive, air-cooled

The CRETO 24 is a creasing tool for creasing solid cardboard, honeycomb materials, and polypropylene.

The CRETO 24 is a creasing tool for creasing solid cardboard, honeycomb materials, and polypropylene. The CRETO 24 was developed for accommodating crease wheels with a diameter of up to 24 mm/0.94 in.

- Crease widths of 0.7/1.1/1.5/3 mm

- Crease-wheel diameters of up to 24 mm/0.94 in

Different material properties require different creasing tools.

The CRETO 61 is the perfect tool for creasing honeycomb materials and single-wall corrugated cardboard.

CRETO 61 produces high-quality creases with or against the corrugation, without any tearing. A well-designed click system enables quick and easy crease-wheel changes.

- Creasing angles of 5°, 10°, and 15°

- Crease-wheel diameter of 61 mm/2.4 in

The CRETO 150 is designed for creasing double- and triple-wall corrugated cardboard.

The CRETO 150 is designed for creasing double- and triple-wall corrugated cardboard. When combined with the AUTOMO L, the CRETO 150 can achieve a creasing pressure of up to 50 kg/110 lbs. This results in quality creases with or against the corrugation, without any tearing.

The CRETO 150 is equipped with a click system, which makes inserting crease wheels very easy.

- Creasing angles of 10°, 15°, and 20°

- Crease wheel diameters of up to 150 mm/5.9 in.

- AUTOMO L required

PERTO is designed to hold perforating knives.

The PERTO has been specially developed for holding perforating knives. The ingenious click system makes it easy to use Zünd’s high-quality perforating knives. The PERTO is the ideal tool for the flawless perforation of corrugated and solid cardboard, polypropylene boards, or plastic films.

- Click system makes it easy to use perforating knives

- Perforation lines of 1.5 to 25 TPI

- Maximum cutting depth of 4 mm

The VUTO enables the creation of angle cuts and V-grooves.

The VUTO enables the creation of angle cuts and V-grooves. The user can select angles in half-steps from 0° to 60°.*

The selected cut angle is then set automatically, enabling the user to cut as many different angles as desired within a job or between jobs. There is no need to retool manually.

* Fine adjustment range for 0° cuts up to -0.5°, for 60° angles up to 60.5°

- Angles can be selected in half-steps from 0° to 60°

- Use with AUTOMO E

Maximize Profits and Minimize Costs

Still looking for answers?

Contact us for more information, a demonstration, and anything else to do with digital cutting.