Q-Line Digital Cutter

Extraordinary performance in digital production!

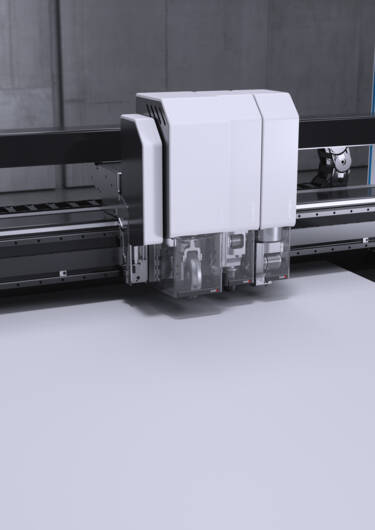

The Q-Line stands for maximum efficiency, superior precision, and reliable automation in modern production environments. Developed for demanding industrial applications, this line of Zünd digital cutting systems offers outstanding cut quality, high process reliability, and intelligent workflow integration. Thanks to innovative technology paired with robust construction, the Q-Line ensures high productivity from start to finish, ensuring flawless, flexible operation in high-volume as well as variable production environments.

Experience the many ways the Q-Line can take your production to the next level!

Seamless integration in automated, industrial-scale production

In highly automated production environments, the Q-Line sets new standards in terms of efficiency. As an integral part of industrial workflows, it enables seamless data integration and maximum processing efficiency. With its advanced engineering, Q-Line can easily cut even very challenging materials, such as composites, with ultimate precision and process reliability. Whether in the aerospace industry, automotive sector, or other high-performance applications, Q-Line offers consistently high quality at an industrial level.

Maximum productivity for packaging and displays

In packaging and display applications , the Q-Line delivers unprecedented efficiency, flexibility, and automation. From prototyping to higher-volume production, it enables high-precision cutting of many different kinds of materials. It integrates perfectly into digital workflows, boosts production speeds, all while simultaneously reducing material utilization and costs. Packaging manufacturers benefit from extremely short setup times and maximum repeatability, which translates into cost-effective, sustainable production at the highest level.

Q-Line - Overview of technical innovations

Cutter sizes

The Q-Line comes in three sizes. Choose the right machine size for your production processes and material sizes - whether you produce batch size 1, small or large runs.

"We have significantly increased capacity and sales"

Dutch printer GBG relies on the Q-Line to take its board and packaging production to a new level of productivity. With significantly higher cutting speeds, improved cut quality, and automated processes, the company has not only increased efficiency, but also won larger jobs and new customers.

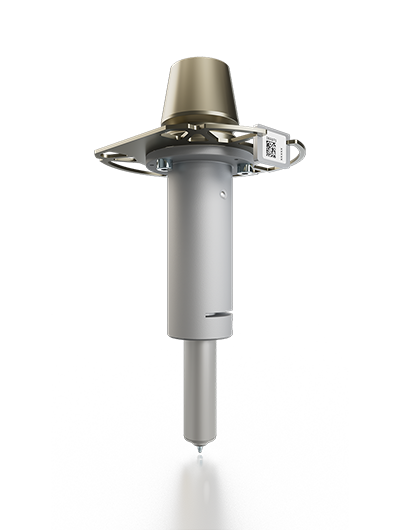

Digital tool management

Q-Line Tool Management makes digital finishing more economical than ever. Tool management is completely handled by the Tool Management Client Tomac, which guarantees simple and automated processes. The digital networking of tool presetting and assembly optimizes tool management and saves valuable time.

AUTOMO is compatible with a wide range of tools.

AUTOMO is compatible with a wide range of tools. To best meet different application requirements, the modules are available in two versions.

AUTOMO serves as a carrier module for many different tools. Compatible Zünd tools can be used in a wide range of applications and require different properties.

The AUTOMO E carrier module features the latest drive technology for maximum acceleration and processing speed. The AUTOMO E offers excellent downward pressure of up to 20 kg/44 lbs.

- Mass: 5,8 kg | 12,8 lbs

- Adjustable clamping force: up to 20 kg

- Lift speed: 500 mm/s | 20 in/s

- Z acceleration: 10 m/s2 | 33 ft/s2

- Pneumatic clamping system (tool fixing), automated picking/replacing of tools from the tool magazine

- Compatible with Q-Line

The AUTOMO L is the carrier module for large tools such as the CRETO 150 but can also hold all other tools from the latest generation. The newly developed motor drive can produce a downward pressure of up to 50 kg /110 lbs.

- Mass: 7,2 kg | 15,9 lbs

- Adjustable clamping force: up to 50 kg

- Lift speed: 300 mm/s | 12 in/s

- Z acceleration: 10 m/s2 | 33 ft/s2

- Pneumatic clamping system (tool fixing), automated picking/replacing of tools from the tool magazine

- Compatible with Q-Line

The UNITO allows you to process many different materials precisely and efficiently.

The Universal Cutting Tool is capable of processing (via Thru Cut) many different types of materials precisely and efficiently.

The UNITO is a very versatile tool for cutting with drag knives. It is excellent for through-cutting a wide variety of materials. The use of drag knives enables very high processing speeds.

- One tool, two processing methods - through-cutting and scoring

- Accommodates centered drag knives UNITO C-6 (0.63 mm) and UNITO C-15 (1.5 mm)

- Accommodates off-centered drag knives UNITO E-6 (0.63 mm) and UNITO E-15 (1.5 mm)

DRAWTO is a cost-effective tool for precise marking and drawing.

DRAWTO is a cost-effective tool for precise marking and drawing on textiles, leather, rubber, or Teflon.

The DRAWTO is a drawing and marking tool. You can use the DRAWTO to easily add assembly markers, dash symbols, or lettering to different materials. DRAWTO accommodates standard drawing tools and cartridges, like ballpoint pen refills or felt-tip pens in different thicknesses.

It is mainly used to produce patterns in the textile and leather industries.

- Accommodates ballpoint-pen cartridges/refills

- Easy cartridge replacement/changes

The ELOSTO is a universal cutting tool for processing many different materials.

The ELOSTO is designed for oscillating cutting. The powerful, aircooled electric drive is able to reach very high RPM levels, ensuring maximum cutting speeds and therefore incredibly efficient cutting. ELOSTO is available with a 0.5 mm, 1 mm, 2.5 mm or 5 mm stroke depending on the application.

- ELOSTO 5

Knife stroke 0.5 mm - ELOSTO 10

Knife stroke 1.0 mm - ELOSTO 25

Knife stroke 2.5 mm - ELOSTO 50

Knife stroke 5.0 mm - Accommodates oscillating blades with thicknesses of 0.63 and 1.5 mm

- Powerful electric drive, air-cooled

Still looking for answers?

Contact us for more information, a demonstration, and anything else to do with digital cutting.