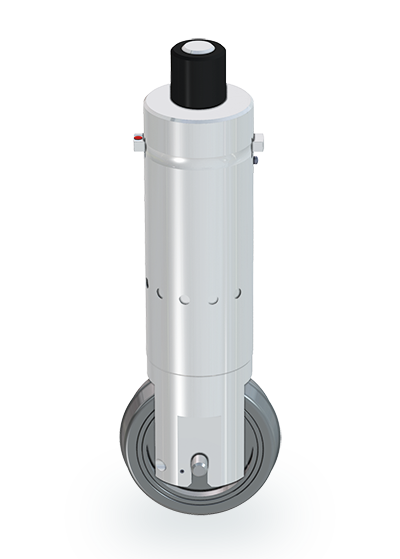

S3 Digital CNC Cutter

Compact, flexible, and economical: The Zünd S3 cutting table is extremely fast thanks to smart technology.

Modular design for maximum flexibility & speed

Our cutting solutions are well known for their extraordinary modularity. The super-fast S3 line of cutters is no different – it can be changed, expanded, and upgraded any time to meet new requirements with the modular tool and material handling systems. Zünd’s modular design concept lets you customize a cutting solution according to your specific production requirements.

S3 Cutter overview

With 6 different cutter sizes, the S3 line lets you select the perfect machine size for all your applications. Our digital cutting systems are intelligent, efficient, and ready for the future.

The construction and design of the S3 are tailored to the needs of our customers. Simple, user-friendly, and ergonomic operations are the result.

The S3 digital cutter is fast. The basis for the S3’s outstanding productivity are intelligent control software, a fast drive system, and cutting technology perfected over many years. Zünd tools optimally designed for use on the S3 complete the system.

The S3 multi-functional cutting system allows for many and variable cutting processes. With the addition of sophisticated material handling solutions, you can increase production capacity many times over.

The price-performance ratio of the S3 cutter series is excellent. Only the most modern technology and highest-quality components are used. The flexibility, reliability, and quality of the S3 cutter cannot be matched by any competitor.

Zünd’s distinctive modular design is truly unique and allows you to configure the required tooling in a few quick, easy steps. Our cutting systems are a safe investment and offer maximum value retention.

S3 cutter sizes

Choose from 6 different sizes to select the perfect machine for your application

Zünd S3 – fast, compact, safe

The S3 is fast, compact, and complies with the highest safety standards. Innovation distinguishes every aspect of Zünd cutting systems. This solution is a true Swiss quality product – uncompromising in precision and design! It lets you produce efficiently and wow your customers with perfect results.

You have the flexibility to choose precisely the tools you need for the job at hand. Combine the required tools based on your specific requirements. You can equip the S3 with up to two different tools.

The S3 features an acrylic vacuum plate. The vacuum holds down the material and is steplessly adjustable across the width of the machine. An energy-efficient vacuum generator provides optimal hold-down.

Automate picking and sorting of cut parts with a collaborative robot. This enhances the level of automation of your cutting solution and increases productivity. The collaborative robot requires no cage or other protective devices.

The intelligent control technology behind the S3 is particularly impressive. It delivers exceptional performance by combining carefully optimized cutting technology with a precise, maintenance-free drive system.

An automated initialization system is used for tool setup. It helps the cutter determine the proper cutting depth quickly, precisely, and efficiently.

The S3 in action

High-performance modules & tools

Find the right modules & tools for every application.

The CTT1 is perfect for processing single-wall corrugated boards.

The CTT1 is perfect for processing single-wall corrugated board. The tool accommodates crease wheels with a diameter of 61 mm/2.4 in and a width of 20 mm/.8 in. Fully supported by the cutter software, the tool produces high-quality creases both with and against the corrugation without tearing or cracking the top sheet. The crease wheels simply snap into the holder, making them very easy to insert and replace.

- Clean creases without tearing

- Directional pressure adjustments

- Crease wheel diameter: 61 mm / 2.4 in

- Crease wheel width: 20 mm/.8 in

- Crease wheels snap into holder

- Compatible with G3, S3, D3

Universal creasing tool for folding carton, polypropylene, twin wall, etc.

Universal creasing tool for solid cardboard, PP, or corrugated boards. For crease wheels with diameters of up to 24 mm/0.94 in.

- Clean creases without tearing

- Directional pressure adjustments

- Compatible with G3, S3, D3

Suitable for fabric and technical textiles. The driven rotary blade allows for very high processing speeds.

The Driven Rotary Tool is designed for cutting all manner of textiles reliably and economically. The material is cut with a motor-driven ten-segmented blade. The blade geometry reduces the drag force on the material considerably and also helps cleanly sever thread or fiber. This processing method produces clean, precise cuts even on very loose, coarsely knit materials.

Choice of two RPM setting depending on the application. Also suitable for cutting materials with low melting points.

- Use of rotary blades reduces drag on the material

- Choice of 2 RPM settings (20,000/12,000 rpm)

- Clean separation of each thread or fiber

- Compatible with G3, S3, D3, L3

Cutting tool with high oscillation frequency for soft to medium-density materials.

The Electric Oscillating Tool is suitable for cutting soft to medium-density materials. The high oscillating frequency enables high processing speed and efficient throughput.

Depending on the application, the EOT is available with 0.5 mm or 1.0 mm stroke. To accommodate different substrates and levels of detail, Zünd offers a wide range of both flat and pointed oscillating blades.

- Depending on application, available with 0.5 mm or 1.0 mm stroke

- Perfect for cutting detailed contours

- Very high stroke frequency

- High processing speeds

- Compatible with G3, S3, D3, L3

S3 Modular material-handling solutions

Downloads

Questions?

Contact us for more information, for scheduling a demonstration, and for anything else you might like to know about digital cutting.