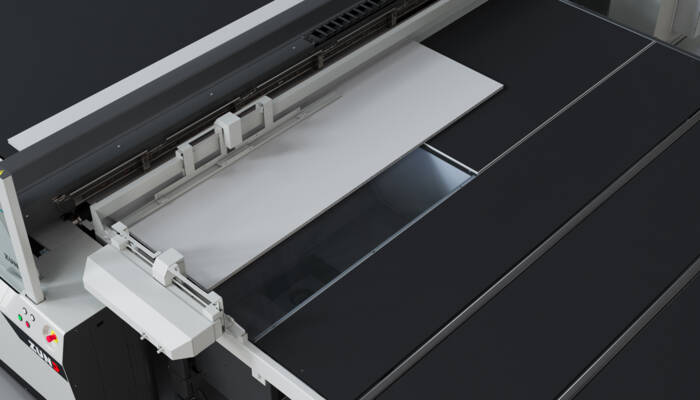

Board Handling System - BHS180

Increase your productivity and eliminate downtime with fully automated material transport from pallet to pallet. Operator intervention is reduced to a minimum. The Q-Line with BHS180 removes bottlenecks associated with manual material handling in your production workflow.

Custom order processing, from one-offs to medium runs, requires a seamless and transparent flow of data. Using QR codes, the system captures the embedded data associated with each job and thus ensures intelligent, error-free QR-code-based production. It allows processing different jobs within a stack, and production of each individual job can begin automatically.

UNDERCAM – the ultimate in efficiency

The UNDERCAM integrated in the board feeder captures the precise location of the graphics printed on the board. It reliably detects any distortions in the print and perfectly matches the cut to the print every time. With every scan, the software adjusts the cut paths to the printed image, on the fly and in real-time, significantly reducing the cycle time for each job.

Identifying the board position

Sensors on the board feeder identify the material edges for proper alignment. If the board is not within tolerance, the board feeder grabs it once more and realigns it so that it can be fed onto the cutter without interruption. This allows even imperfectly stacked materials to be processed, which further streamlines the production workflow.

To ensure reliable board and sheet separation during the loading process, redeveloped suction cups can be individually adjusted for different materials via Zünd Cut Center – ZCC.

Perfect unloading and stacking

The innovative design of the off-load system allows bridge-free cut boards to be stacked easily and reliably, making it easier to handle completed jobs in the stack. Different jobs are stacked slightly offset, which speeds up the subsequent job separation by the operator. Any faulty boards are also set aside with an offset and are therefore easy to spot as the pallet is removed.