3.6 kW Routing System RM-L

The router module RM-L with a powerful 3.6 kW spindle is the most efficient system for high-precision routing, polishing, and engraving of aluminum, wood, plastics, and composite materials.

3,6 kW Routing System RM-L

High-powered 3.6 kW spindle

At the heart of this routing system is a powerful water-cooled spindle with a pneumatic clamping system. With up to 3.6 kW of power and 0.7 Nm of torque, this exceptionally robust and powerful tool can cut through hard, dense materials at much greater processing speeds. At the same time, this tool allows for greater cutting depths when processing thick substrates, which in turn reduces the number of passes and significantly increases throughput.

Clamping system

To ensure easy handling, the system uses HSK-E25 collet holders. Even a manual tool change can be performed in a matter of seconds. What further facilitates this, is a dust collar that retracts automatically and provides optimal accessibility. ER-16 collets provide perfect concentricity and reliable clamping even in the most demanding applications. They are also capable of accommodating bits with different shaft diameters up to 10 mm.

Minimal quantity lubrication - MQL

The RM-L is equipped with a minimal quantity lubrication system that coats the cutting surfaces of the router bit with a thin film of lubricant to minimize friction. At the same time, heat buildup is reduced even further with pressurized air. The MQL system, therefore, enables much more efficient and economical processing of solid aluminium.. When routing aluminium composite materials (ACM), the lubricant also helps extend bit life.

Details

- Routing depth up to 50 mm / 2 in.

- Clamping system: HSK-E25

- This router module can be mounted only at position 2

Benefits at a glance

- Powerful 3.6 kW router spindle for maximum efficiency.

- Ideal for processing aluminium, wood, plastics, composite materials.

- Outstanding speed and productivity with fewer passes when processing thick materials.

- Minimal quantity lubrication permits processing aluminium and extends bit life when processing aluminium composite materials.

- ER-16 accommodates router bits with different shaft diameters up to 10 mm.

- Fully supported in Zünd Cut Center - ZCC software.

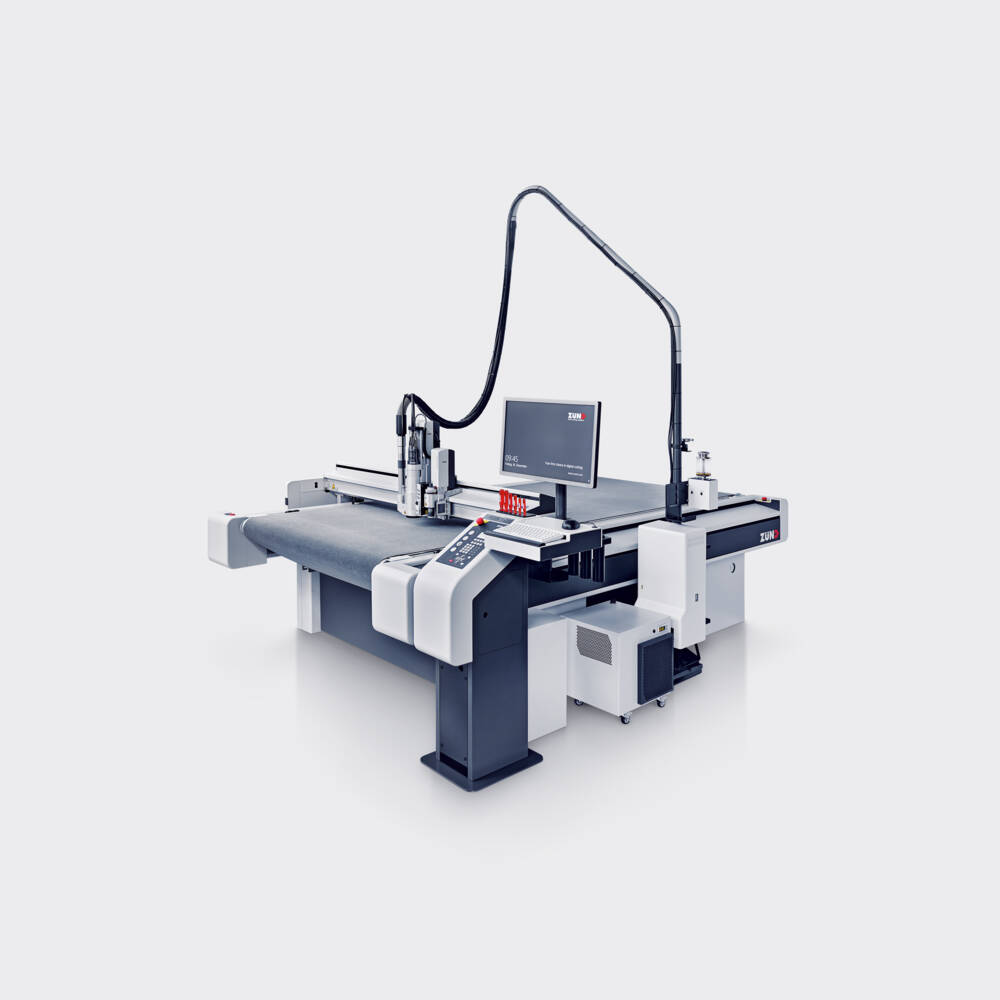

Efficient dust extraction, various options for tube guidance

A high-performance dust extraction system keeps the working area clean. It also increases productivity by minimizing the amount of time spent on manual cleanup. The amount of suction generated by the system is user controllable. By adjusting it to meet specific job and material requirements, the user can keep small parts from being lifted and sucked into the vacuum system. Depending on the cutter size and location requirements, the suction tube can be suspended above the machine either with a freestanding gantry or a guide system mounted to the ceiling.

Cooling unit

For maximum efficiency, the router spindle is equipped with an integrated water-cooling system. For ease of use, the required cooling unit has casters and can be refilled with minimal effort.

Automatic Router bit Changer – ARC HSK (optional, available only for G3)

From loading the collet holder containing the correct bit to initializing and cleaning, the automatic bit changer ARC HSK completely automates bit handling. The ARC magazine can accommodate up to eight different preloaded collet holders. It helps keep the time required for bit changes to minimum, which significantly impacts productivity. This is especially true for workflows that involve many different custom or short-run jobs or complex designs that call for several different types and sizes of bits. The ARC further automates the operation of the Zünd cutter and, in conjunction with the 3.6 kW RM-L router, generates unprecedented routing efficiency and profitability.

Reliable routing underlay

Sealgrip™ underlays permit high-precision routing of very small parts. Sealgrip™ is a very porous, clingy material that prevents lateral movement of the material.