UNDERCAM is a technology from Zünd that allows printed materials to be registered precisely and efficiently on third-generation cutters and the Q-Line with BHS180, thereby saving time and resources.

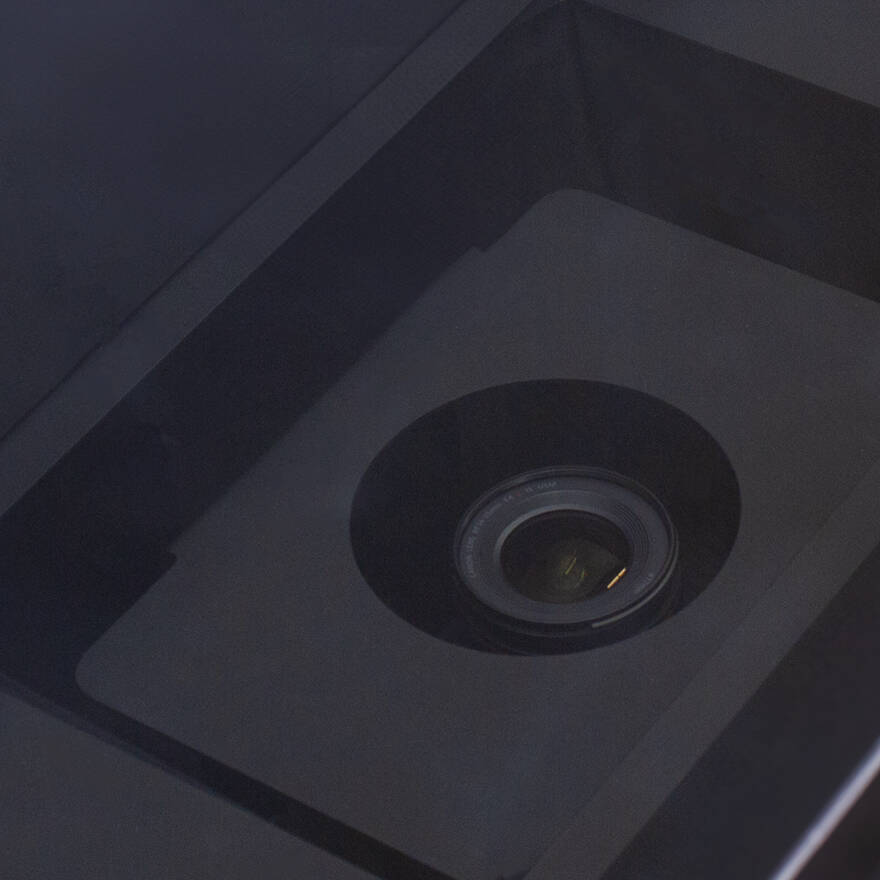

As the name suggests, the UNDERCAM captures the board from underneath with the printed side facing down. In the case of the BHS180 Board Handling System, the UNDERCAM is integrated in the board feeder. To enable compatibility with the cutters from the G3 and D3 series, the UNDERCAM is available in combination with a board-loading extension.

The UNDERCAM reliably identifies any distortions in the print and ensures the cut is perfectly matched to the print every time. With every scan, the software adjusts the cut paths to the printed image in real time, making the cycle times per job even shorter.

Benefits at a glance

- Increased efficiency: No more time-consuming, separate capture of register marks required.

- Time saving: Automatic identification of the next job while the cutter is operating.

- Flexibility: Identification and processing of the job with the printed side facing down.