IVE Group sets new performance standard with Zünd installs

IVE Brand Activations has ramped up its production capabilities following the recent installation of a new Zünd D3 3XL-3200 and BHS150 at its production facility in Braeside, Melbourne.

The new machine was installed by Zünd Australia in September 2024. IVE already operates three G3 Zünd digital flatbed cutters in Melbourne and one G3 model at its facility in South Granville, Sydney.

“Due to their productivity and size, the existing Zünd G3 3XL-3200 cutters have been the workhorses for IVE’s digital cutting needs, cutting a range of materials from flexible materials such as SAV, banner, and Yupo, through to carton, corrugated, foam board, and honeycomb board,” said Gittus.

A Strategic Move Towards Enhanced Cutting Power

The conversation with IVE around enhancing its cutting power and automation initially commenced in early 2023. At the time, IVE was looking to expand its carton and corrugated POS business and move work from traditional die cutting, resulting in the need for additional digital cutting production. IVE performed extensive market research into available solutions to meet the company’s needs. This involved a proof-of-concept component involving a series of material handling and cutting and creasing processing speed tests.

IVE provided 30 different files on E-flute and B-flute for the cutting and creasing speed testing. After running the tests and the numbers, IVE was convinced the Zünd D3 3XL-3200 and BHS150 systems delivered the best productivity in the market for its needs.

“There was a lot of due diligence around this machine and other competitor machines. We have a broad range of customers, and our corrugated displays are not cookie cutter – there’s a lot of theatre and intricacies. We did test files and ran simulations but, in the end, we knew Zünd was the right choice for us,” Gittus said.

Increased Cutting Capacity and Automation

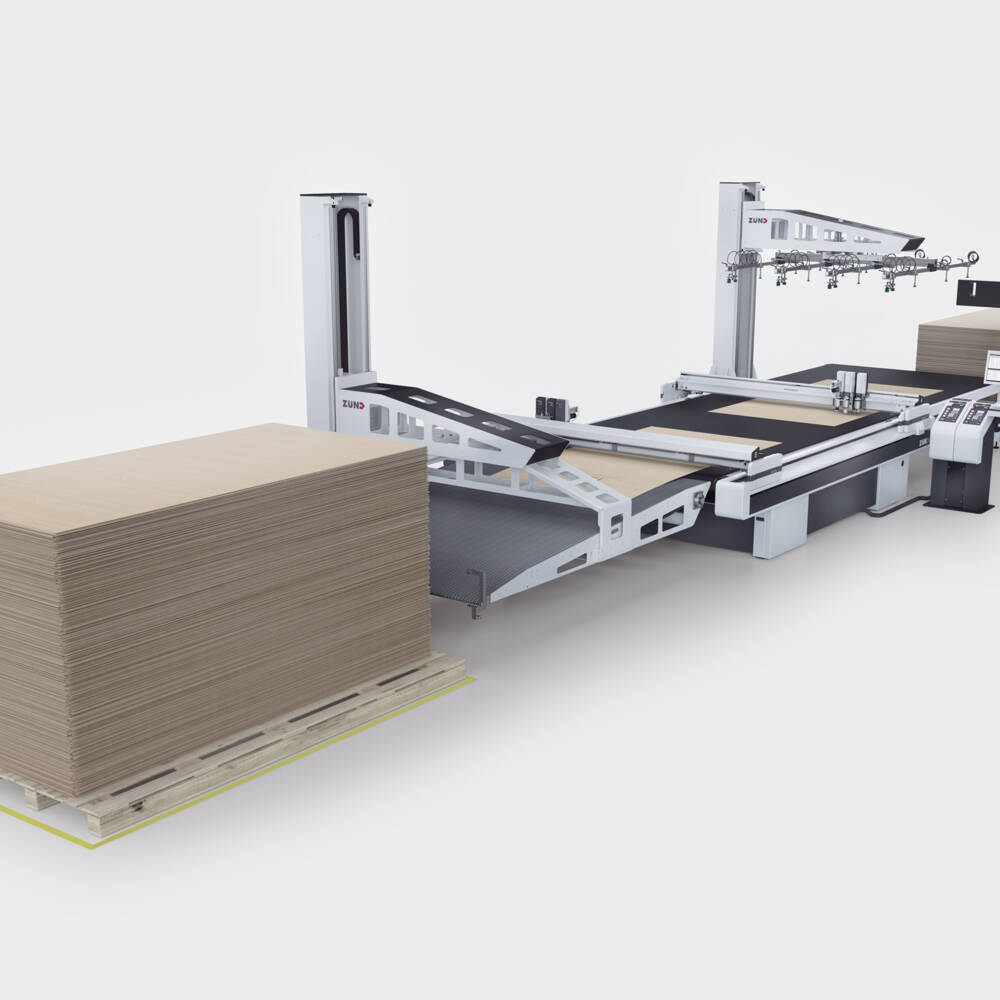

The D3 3XL-3200 sets new performance standards with its innovative dual-beam system and twin tool sets, enabling IVE to cut and crease each sheet in half the time it did before.

The D3 model also provides significant cutting speed advancements over IVE’s existing G3 machines. Additionally, the cutting table width of 3200mm and length of 3200mm enables IVE to load two standard size boards onto the cutting bed and cut both sheets simultaneously.

Configured with the BHS150 automatic board handling system, this converts the digital cutting system into a pallet-to-pallet production system, resulting in significantly longer uninterrupted operating time, or the need for down time, as it automatically loads two boards and cuts and creases and unloads and stacks simultaneously. It also provides IVE with ‘lights out’ cutting production, leaving the machine operating unattended at night, which Gittus says has been a game changer.

Cutting-Edge Software: ZCC Zünd Cut Center Version 4

“The increased capacity with no labour has been a massive win for us,” he said.

The machine also operates with the latest version of Zünd Cut Center (ZCC). ZCC is the command centre for production and also controls the material-handling systems operators use for loading and unloading. ZCC Version 4 supports operators with smart, intuitive digital-cutting functions throughout the production workflow. Version 4 also offers further capabilities for flexible, automated file preparation, and efficient digital cutting via touchscreen.

The installation was led by Zünd Australia’s technical sales and applications manager, William Berlowitz. “The commitment by the Zünd Australia team was A1,” Gittus said of the installation process. Building on its fleet of Zünd machines, IVE NSW also recently updated its cutting fleet with a new Zünd G3 3XL-3200 and front extension table. IVE NSW had been operating two older model PN series Zünds and decided it was time to update to deliver more cutting power and functionality.

Zünd Australia: A Growing Presence in the Local Market

Zünd Australia is a wholly owned subsidiary of Zünd Switzerland and commenced business in March 2024, with Dale Hawkins at the helm of the new organisation. “We have a highly experienced technical team with a long association with Zünd products. Our technicians are all factory trained,” Hawkins said. This year, Zünd is looking to continue to expand across the local market. The company recently moved into its new headquarters with dedicated showroom in Cheltenham in Victoria.

This first appeared in the February issue of ProPrint magazine. Read the original article here.