MANN+HUMMEL elevates production with Zünd investment

MANN+HUMMEL, a global leader in filtration technology, has significantly improved its production capabilities by investing in a Zünd G3 L-2500 cutting system for its air filtration products in the Life Sciences & Environment division.

MANN+HUMMEL specialises in developing high-performance filtration solutions for a diverse array of applications, from passenger cars and commercial vehicles to industrial machinery and rail transport. The company is committed to sustainability and the efficient use of resources, contributing to a cleaner planet. In 2023, MANN+HUMMEL, with over 22,000 employees across more than 80 locations, generated a turnover of EUR 4.7 billion.

Andy Munroe, Maintenance Manager at the UK filtration products site in Lancashire, highlighted the company’s dedication to innovation and environmental protection. “Our entire business revolves around creating clean air. Our solutions are utilised globally to safeguard people, processes, equipment, and the environment,” said Andy.

In 2023, Andy led the digitisation of production at the Lancashire site. Noting the advanced capabilities of Zünd technology at other MANN+HUMMEL locations in Sweden, Germany and Denmark, he identified the significant value and flexibility it could bring to the UK facility. “The UK site, part of the Life Sciences and Environment division, supports various industries, including hospitals and research centres. We provide bespoke solutions for both low-volume and high-volume projects alongside our standard products,” Andy explained.

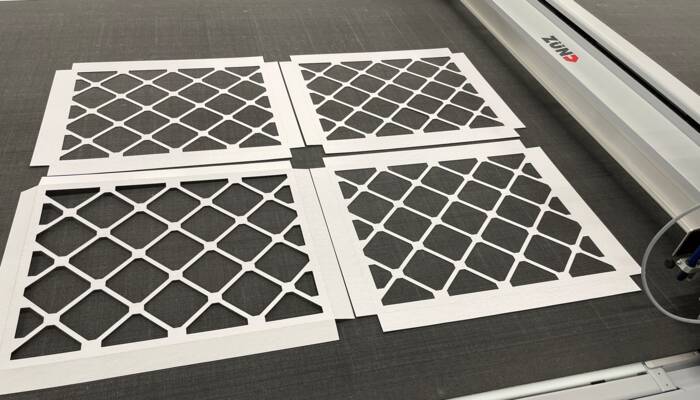

The Lancashire site produces a range of filtration products, including bag filters, synthetic fibre filters and filtration panels. Andy noted, “One challenge with non-standard products was the labour-intensive process of preparing materials for manufacturing. Materials required trimming with an industrial guillotine before being hand-cut and stapled.”

To address these challenges, Andy led a continuous improvement project and coordinated a demonstration of Zünd’s cutting technology. “I needed to present a compelling case to digitise our cutting process. Testing various materials on the Zünd was crucial,” Andy said. The Zund team performed multiple test cuts, demonstrating the system’s versatility and precision.

Andy was particularly impressed by Zund’s professionalism and willingness to accommodate their specific needs. “The Zünd team went above and beyond, allowing us to fully explore the system’s capabilities. We also discovered that Zünd could process corrugated boxes, which was an unexpected bonus, especially for our beverage board manufacturing,” he remarked.

The successful demonstration led to the investment in the Zünd G3 L-2500, significantly enhancing the site’s productivity and flexibility. “Digitising our cutting process with the Zünd system will have a substantial positive impact on our operations,” Andy concluded. Following a comprehensive CAPEX review, MANN+HUMMEL selected the Zünd G3 L-2500 for its capacity to handle both roll materials and corrugated cardboard efficiently.

Reflecting on the investment six months later, Andy emphasised the transformative benefits of the Zünd system. “The Zünd has greatly enhanced our manufacturing process with its cutting speed and advanced nesting capabilities. We are saving 30% on raw material usage and our productivity has increased by 40%. The multifunctional digital cutter also allows us to introduce new materials into the process, such as corrugated cardboard, with the assistance of the Electric Oscillating Tool (EOT),” Andy detailed.

The integration of the Zünd G3 L-2500 exemplifies MANN+HUMMEL’s commitment to leveraging cutting-edge technology to drive efficiency, innovation, and sustainability in its operations. This strategic investment not only improves current production capabilities but also positions the company to adapt swiftly to future market demands and material innovations.