Cristex Increases Cutting Capacity with a Second Zünd Investment

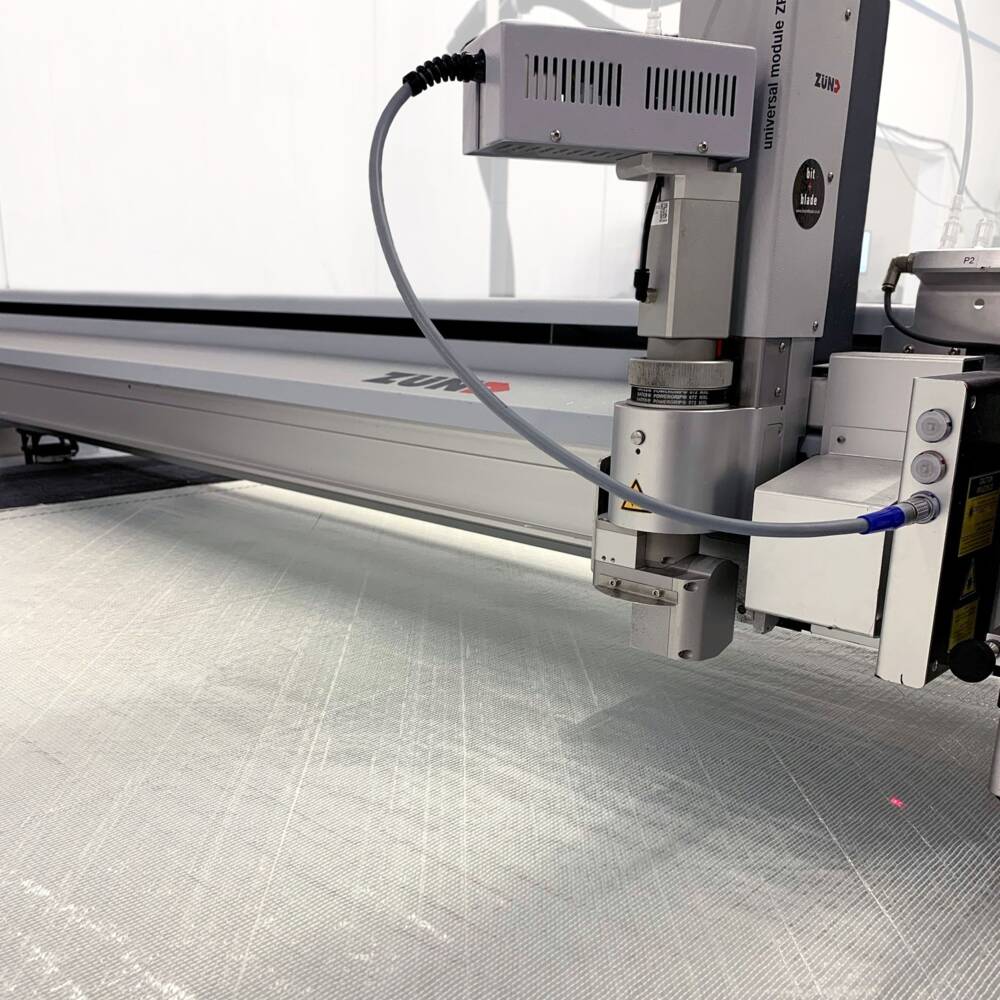

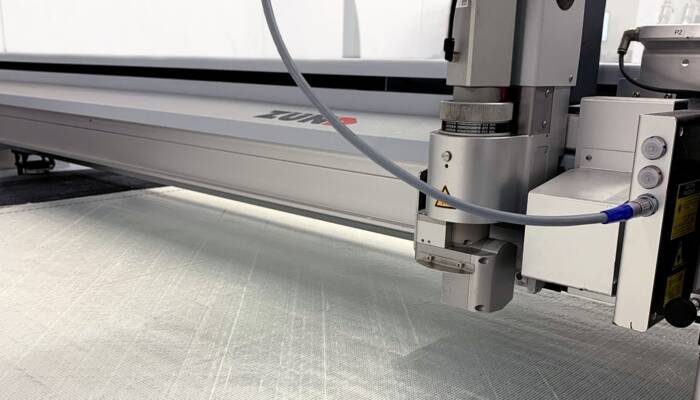

Cristex have added a second Zünd G3 L-3200 as part of a strategic investment to meet an increased demand within their cutting and kitting division.

Formed in 1990, Cristex Composite Materials have steadily evolved to become one of the UK’s premier suppliers of high-performance fibres and fabrics for the UK Composites and reinforced plastics markets. Cristex supplies a comprehensive range of products manufactured from Glass Fibre (E.C.S. ECR), Carbon Fibre, Aramid Fibre, Dyneema®, Thermoplastic as well as Epoxy Resins and Adhesives.

Building on their remarkable success as a leading composite material supplier, Cristex took a progressive step by introducing their cutting and kitting service in 2019. Scott Singleton, Operations Manager at Cristex Composite Materials said “At Cristex, we understand that as the market evolves, customers need us to be more than just a material supplier. It is important to integrate technological solutions using innovative ideas to support various markets. Our first Zünd cutter investment is a good example of this. Many of our customers in the marine, automotive and other markets were hand-cutting their roll materials. By Investing in our first Zünd G3 L-3200, we were able to enhance our customer offering with our cutting and kitting service, which has since become very popular. Customers no longer have to waste time hand cutting materials using cardboard templates and compromise on cutting accuracy. Furthermore, by using us to digitally cut their 2D parts reduces material wastage by almost 40% thanks to the Zünd nesting algorithm.

Since introducing the cutting and kitting division, Cristex have seen an increased demand for this service. Scott explains “Many of our customers are now using our cutting and kitting service for their dry and pre-preg carbon fibre, as well as glass fibre jobs. Our Zünd cutter runs at full capacity with an increasing backlog of orders. With the cutting and kitting division being a very profitable part of the business, it made sense to re-invest in a new digital cutter to increase our growth.”

Earlier this year, Cristex took the decision to invest in a new digital cutter to increase production capacity. Scott said “We looked at Zünd and some alternative manufacturers but quickly came to the decision that Zünd was the best option for us. The support from Zünd over the years through our first digital cutter has been excellent and we couldn’t fault their service. Furthermore, their modular offering was very attractive, because we could pick and choose the options which met our business requirements. With other digital cutter manufactures, we were stuck with pre-defined configurations of cutters that weren’t flexible for our business demands. This gave us enough confidence to re-invest in another Zund cutter”.

Cristex invested in another Zünd G3 L-3200 but added a Leibinger Jet 3 Inkjet Printer which allows them to print characters and barcodes as part of the material cutting process. Scott said “Having the ability to print instructions on cut parts further enhances our customer offering through technological investment. Customers can now have laminating guidelines printed on each cut part, which means that any skilled laminator can pick up the part, follow the instructions, and correctly apply the cut parts. Laminating guidelines can also include placement orientation information or part numbers if working with multiple kits.”