EasySkinz increase cutting productivity

Award-winning mobile device skin manufacturer EasySkinz has opted for a new Zünd Cutter G3 L-2500 digital cutter to achieve optimum precision and productivity.

EasySkinz began with one simple promise, attractive wraps that keep the original design and style of the device. The idea started as a family reaction against the bulky and unattractive cases on the market which hid the essence of the devices and rapidly grew to a successful family business shipping its products to 140 countries a month. With a professional background of more than 27 years in the design industry, EasySkinz is now a leader in manufacturing the highest quality skins and meeting the needs of more than 300,000 customers all over the world.

The company is at the forefront of the UK and the USA custom, made-to-order skin manufacturing market and produce the most advanced tailor-made skins for smartphones, tablets, computers, laptops, and game consoles. Their products blend high-quality protection from scratches, dents, dust, wear-out with attractive, tailor-made designs without adding any bulk.

Angel Totochev, Director at EasySkinz Ltd said “At EasySkinz we keep the original design of the device while we add individuality to it. With our wraps you will always stand out from the crowd with a new colour or a picture that resonates with your favourite outfit, styling, or car colour. With EasySkinz it is almost impossible to see another person with the same wrap as yours. Our professional designers put their hearts into creating new forms, designs, and ways of application and this makes our skins exclusive for every model.”

In recent years, the company has faced a growing challenge of cutting intricate skin parts for new mobile devices. With technology developing and mobile devices becoming more and more compact with smaller charging ports and built in speakers, precision has become more important than ever. The company’s vinyl cutters were quickly finding themselves out of their depth with intricate parts requiring better cutting accuracy.

Angel has always been an admirer of the Zund Cutters for many years and decided it was time to invest in a purpose-built digital cutter which will give him the precision he requires. Having spoken to Zund UK, he decided to send in some materials for testing and was very impressed with the 0.2 mm tolerance Zund achieved and booked a demonstration day.

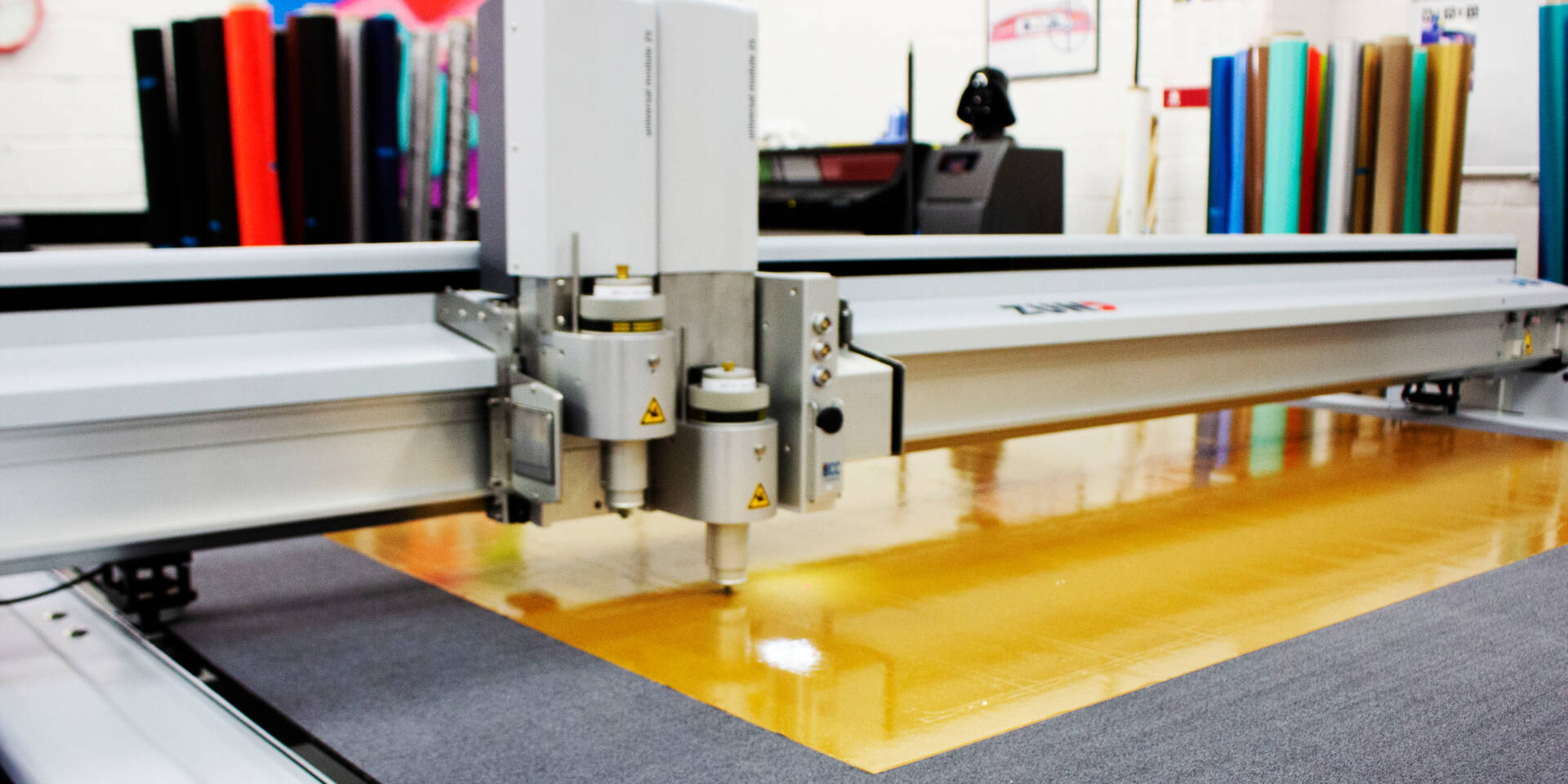

During his demonstration day at the Zund UK HQ, Angel quickly realised the other benefits the Zund technology would bring to his business. Angel said “Previously when we processed self-adhesive vinyl rolls on a conventional vinyl cutter, we had to factor in the moving compensation when designing our skin cases, because the roll of material would move back and forth when cutting. This was a nightmare for our designers and involved a lot of trials and errors. The Zund is great at overcoming this problem because of the way the flatbed cutter holds the material with its vacuum, allows the material to be much more stable and the beam does all the moving and cutting, so we gain exactly what we designed.”

The cutting precision wasn’t the only impressive factor that led to Angel ordering his new fully specified Zünd Cutter G3 L-2500. During the demonstration, the team at Zund showed Angel how to increase productivity using the Zund twin cut technology. One of the benefits of the Zund Cutters is the ability to hold multiple tools on the beam, in this case two Kiss Cutting Tools KCT which work simultaneously to reduce cutting time by 50 %. This was a great added benefit for Easy Skins and meant productivity increased whilst maintaining optimum precision.

Reflecting back on his purchase, Angel said “Our new Zund cutter can cover all of our needs, with amazing quality cuts and productivity. I would like to thank the team at Zund for the brilliant customer service and technical support. Zund spent a lot of time listening to my requirements and working with me to create solutions which will help us take our business forward."