Zünd at JEC World 2025 – Efficient cutting and kitting

At JEC World 2025 in Paris, Zünd will be presenting a comprehensive set of solutions and technologies for efficient, automated cutting of composite materials and technical textiles. As provider of total digital cutting automation, Zünd's focus is on well-designed production processes and workflows. Trade professionals will have the opportunity to see firsthand how seamlessly data management, cutting, and kitting work together in a digital workflow.

From March 4–6, Zünd will be presenting innovative solutions for digital cutting at JEC World in Paris. At Booth S57 in Hall 5, the provider of complete solutions for automated processing of composites will present technologies that seamlessly integrate the production workflow, from file preparation to parts handling and logistics. Show attendees will experience live and in person how digital workflows simplify and speed up not only the cutting process, but also picking and sorting.

Digital, automated, efficient

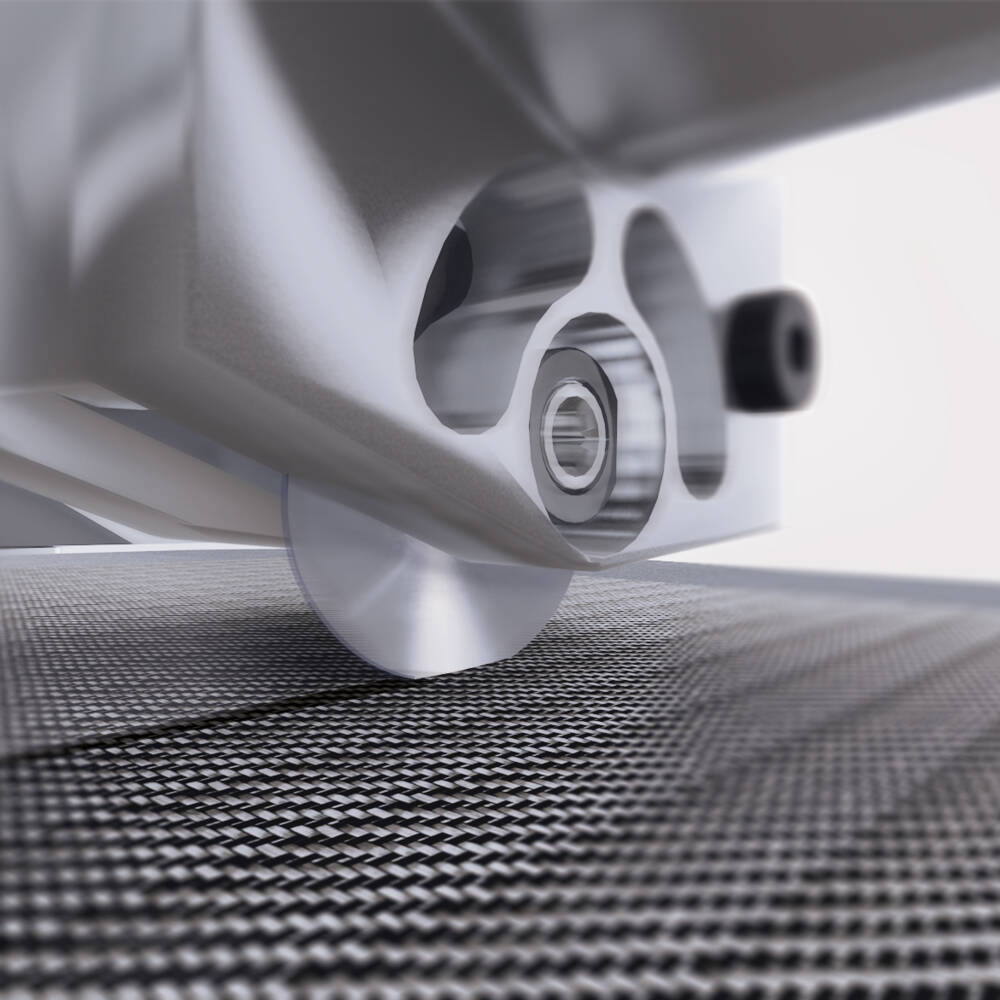

The centerpiece of the Zünd exhibit is a fully integrated production cell that demonstrates how the flow of data and materials can be managed efficiently. The focus is on potential savings through intelligent automation. With optimized material usage, flexible software, and lower personnel costs, companies can sustainably increase their competitiveness. The production cell consists of a Zünd G3 cutter, a ProWinder Vision from material-handling partner CNM, and software solutions from Zünd as well as software partner Jetcam. Among other things, it demonstrates how to minimize waste when cutting fiber-reinforced composite materials. The solution builds on an end-to-end digital workflow in which Zünd PreCut Center ZPC plays a key role. In addition to automatic nesting of contours, which also takes into account irregular material shapes or defects, ZPC enables integrating metadata in the output file. This information is put out to the finished parts with an inkjet or label printer—the perfect basis for kitting, end-to-end trackability, and a more efficient overall production process. For manual parts removal, the system uses an intuitive marking and projection system to visually support the user in picking and sorting cut parts.

Zünd will also be presenting Zünd Cut Center - ZCC V.4, the latest version of its operating software, which offers touch control and even more flexible options for workflow automation. With its wide range of functions for job preparation and cutting, ZCC 4 opens up new possibilities for adapting digital cutting processes to the requirements of the composites industry.

Collaboration with Loop Technology

Another highlight is the collaboration with Loop Technology, also an exhibitor at JEC World. Loop Technology is presenting the high-speed preform system FibreLINE, which is revolutionizing the production of composite structures for aircraft, wind turbines, cars, and trains. FibreLINE recently received one of the coveted JEC Innovation Awards in the “Aerospace Process” category. Zünd cutting technology, specifically the innovative Q-Line, plays a central role in this highly automated manufacturing solution. Trade show visitors will have a unique opportunity to discuss the advantages and possible applications of this innovative solution with specialists at the Zünd booth as well as with Loop Technology representatives directly.