Mind software is the ideal solution for meeting individual requirements in leather and textile cutting. It offers a multitude of powerful functions for all process phases in your digital cutting room. Discover flexible software that makes cutting faster, more precise, and more cost-effective. The software tools from MindCUT are used in a wide range of applications: footwear, fashion apparel, sportswear, and protective clothing, as well as transportation, accessories, upholstery, home furnishings, and even rugs and other floor coverings.

Discover the power of Mind software

Mind software tools support you in all phases of your production workflow, from importing design files to production management, cutting, parts removal, and logistics. Seamlessly integrated with Zünd automated cutting systems, these software tools offer endless benefits and boost your efficiency throughout the production cycle.

Benefits at a glance

- Streamlines production, saving time and money.

- Controls the Zünd cutter, incl. material feeding/advancing and parts removal, facilitates post-production.

- Supports all phases, from part digitization and subsequent data import to capture, nesting, cutting, and parts removal.

- Modular and customizable for individual customer requirements. The software is scalable for any production volume, from samples and small batches to medium and full-length production runs.

- Can be used as standalone solution or integrated in a Production Data Management (PDM) system.

- Thanks to its open architecture, it also works seamlessly with CAD and ERP software as well as third-party sales management solutions.

- With its intuitive user interface and guidance, it enables interventions at the cutter, e.g. during pattern matching.

- Supports both inline and offline workflows.

MindCAD Part Scan

The fastest and most reliable way to digitize model parts and templates

A flexible and automatic part scanner with feature recognition, fully integrated in your digital production environment. All defined properties, processed, and extracted data can be saved instantly for later use.

MindGEST

MindGEST PDM, the perfect solution for efficient Product Data Management in a virtual environment. MindGEST provides continual cost feedback by combining order planning, production and reporting data.

MindGEST PDM simplifies collaboration as well as tracking of the different phases of the product-development cycle. Benefits include collaborative production, integrated information, speed, and efficiency. Through centralized management of product and process data, you can optimize your productivity, shorten development times, and keep pace with dynamic market requirements.

- MindGEST PDM enables collaborative production. The software simplifies communication and the exchange of information among all involved in your production workflow. Use the virtual environment in MindGEST PDM for the collaborative design and development of your products!

- By integrating all of your product and process information in secure, centralized data storage, you can maintain a clear overview of the entire process and maximize the efficiency of your workflows. MindGEST PDM enables easy data management, shorter development times, and optimized productivity.

- MindGEST PDM offers flexibility in a dynamic market environment and helps get your products to market more quickly.

With MindGEST you can

- Implement collaborative production and quickly and easily communicate with everyone involved in product design and development.

- Centrally and securely manage your designs, construction and production data, and libraries.

- Centrally save your vector data, digitized materials, nested layouts, and cut files.

- Conveniently oversee cutting processes and workflows via dashboards.

- Obtain metadata for nesting and parts removal.

- Ensure data protection and integrity with version control and integrated test-data functions.

- Integrate and automate your workflow with MindCAD Part Scan and MindCUT.

- Connect multiple cutters with each other.

- Automate import and export functions.

- Connect ERP software via predefined interfaces.

MindCUT

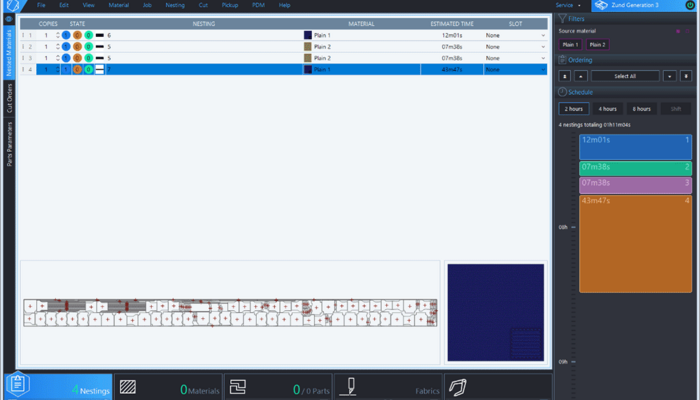

MindCUT is the comprehensive control center for your digital cutting room. This operating software for the footwear, leather goods, transportation, upholstery, and garment industries is exceptionally flexible and customizable and includes all necessary components for digitizing, nesting, cutting, and parts removal. MindCUT gives you easy and intuitive control of everything, from the cutter and material-transport systems to projection and capture via digital cameras.

Studio Modules

MindCUT Studio offers a variety of useful tools for automated cutting, including digitizing, interactive nesting, job management, and cutter control.

- Material digitization and classification, defect handling (vertical and horizontal), and parts placement according to designated zones

- Import of digitized, classified single parts, models, and nested markers

- Extensive options for integration in existing data infrastructure

- Versatile process management, enabling specialized processes such as (digitally) printed cut, pattern matching, and feature recognition for leather and textile applications.

- Manual, interactive, and fully automated placement/nesting of parts

- Support of parts removal and integrated post-cut functions

- Extensive options for online and offline reporting

Model Importer

Using the Model Importer, you can import model vector files. The tool recognizes and classifies the model parts and saves edited part geometries for further processing.

- Import and recognition

- Processing and classification

- Cutting preparation

- Integration (export of prepared parts data into Studio)

Material capture for leather

The software allows you to capture leather hides, interactively or automatically edit contours, defects, and quality areas, as well as manually or automatically nest parts. You can define the stretch direction of the leather and capture material contours and defects. Material capture is fundamental to optimizing layouts, minimizing waste, and achieving optimal material utilization.

The contour of the leather hide, material defects, and up to five quality zones are automatically detected. You can also interactively validate and correct results, as well as define additional quality zones and stretch directions.

Calculate the precise area of the leather material and compare it with the area delivered by the supplier for better cost control.

Nesting, interactive or automatic

Whether you’re dealing with irregularly shaped materials such as leather hides, or textile materials from a roll, you can easily nest pattern pieces interactively on either. You can rotate, arrange, and place them as desired using the mouse. For maximum efficiency, it is possible to distribute multiple jobs over multiple hides with offline nesting.

Mind offers advanced and specialized automatic nesting algorithms for natural materials, combined with interactive tools to further optimize results.

Depending on requirements, you can also have the software automatically nest parts on hides or rolled materials. Parts nesting on patterned roll material will automatically position parts in relation to the pattern.

When nesting, the software takes into account defective areas and quality zones previously defined by you. Scan-to-order and scan-to-stock modes are available for maximum efficiency in multi-part nesting.

Special functions for leather

Inline and offline process

Mind software supports both scan-to-stock and scan-to-order workflows. In the offline process, hide capture, digital marking, classification, and parts nesting is done via standalone solutions such as MindCUT DIVA (digital inspection and virtual annotation) rather than on the cutter. The hides are captured, physically or digitally marked and classified. In the scan-to-stock workflow, hides are digitized and then held in stock until needed for production. In the inline process, by contrast, the hides are captured and parts are nested directly on the cutter.

While the inline workflow offers advantages when it comes to making on-the-fly adjustments because of differences in materials, the offline workflow is ideal in terms of nesting efficiency and productivity.

Special functions for textiles

Pattern matching

Whether it’s polka dots, checks, or horizontal stripes, the software automatically recognizes repeating patterns. Save time with simultaneous model configuration and cutter control. Markers are automatically aligned to account for material distortions and compression. Enhance product quality through high-precision alignment of parts on patterned material. The software instantaneously aligns markers to the pattern while retaining the part size, or adapting it to the pattern, as desired.

Printed Cut

Use Printed Cut for your digitally printed, custom fabrics. Printed Cut allows you to place parts efficiently and consistently according to their contour. The material is aligned using printed reference marks that are automatically detected by optical systems such as the OCC or ICC. Depending on the material type and graphics, different adjustment strategies are available for detection, assignment, and controlling the cut.

Feature recognition

The new feature recognition function saves you valuable time in cutting preparation. Achieve the highest quality standards while simultaneously ensuring high repeatability. Feature recognition automates what was previously a painstaking and time-consuming manual process. With feature recognition, the tedious placement of motifs is a thing of the past – you select the model, define the motif properties, position the various cut parts, and let the software do the rest. The software recognizes the positioning and automatically repeats it along the length of the roll.

Software license

With the one-time acquisition of the software license, you are entitled to use the Mind software in perpetuity. The purchase of the software license also includes software maintenance; the latter is billed annually and ensures you always have the latest version of the software.