The Cutting Edge

Toronto co-packer Promotional Print & Packaging embraces digital technologies and process automation to pave the path for prosperous future. They have nothing but praise for the craftsmanship, performance and reliability levels provided by the Zünd Cutter G3 L-3200 and the Zünd Cutter D3-3200 cutter with a board handling system BHS150.

Longevity and staying power in the highly competitive co-packing business are largely defined by a company’s ability to reinvent itself to meet its customers’ ever-evolving needs and requirements to succeed in the markets they serve. And if the last years are any indication, Toronto-based Promotional Print & Packaging Inc. (PPP) has mastered the art of self-reinvention down to science – in many ways thanks to its willingness and ability not only to embrace change, but to use it as a catalyst for continued growth and success.

Operating as a “One Stop Shop” solutions provider for clients ranging from major multinationals to e-commerce start-ups, the company has invested millions of dollars over the years to equip its two Toronto plants with the latest best-of-breed packaging systems and technologies to offer clients a comprehensive end-to-end suite of product and services that includes retail POP (point- of-purchase) displays; printing and finishing capabilities; distribution and fulfillment services; storage and logistics; and the fast-growing e-commerce custom packaging design and production.

According to PPP president Brandon Townsend, a 2018 move to a new modern location in Toronto’s east end has enabled the 70-employee company to achieve new process efficiencies and accommodate a range of next-generation technologies that have fine-tuned its operational excellence to not only con-solidate its existing client base, but also open new opportunities in the rapidly-growing e-commerce sector that has been growing in gigantic leaps and bounds since the outbreak of the Covid-19 pandemic crisis.

“We have a wide array of blister equipment, shrinkwrapping systems, digital print technologies, wide-format printers, and labeling and boxmaking equipment to enable us to achieve rapid response in our co-packing division and ensure we are making all the in-store dates,” he says.

“Technology is having a profound impact on speed-to-market and demand volatility,” Townsend states. “In a highly competitive market, retailers and their trading partners do not have the luxury of recovering lost sales when opportunities arise, thus the six- to 12-week order-to-ship cycles are no longer an option.” In addition, the accelerated emergence of e-commerce retailing and online shopping is also driving retailers and brand-owners alike to compress their product development cycles, resulting in even tighter deadlines for their co-packing suppliers.

To help these smaller customers bring their innovative packaging ideas and concepts to life, PPP has made significant investments in the digital cutting systems and technologies manufactured in Switzerland by Zünd Systemtechnik AG, and distributed in North America by its Zund America Inc. subsidiary in Oak Creek, Wisconsin. As Townsend relates, “Zund has played a large role in digitizing our production. Our initial relationship came about when we were building our design center in 2019, but it quickly evolved into building a full digital manufacturing production line with extensive automation capabilities,” says Townsend, crediting Zund with helping build a robust Web2print platform that can run around-the-clock and deliver unrivalled speed-to-market. “They have been extremely supportive of our desire to run 24/7 in the dark, meaning unmanned, and to really push the limits of technology.”

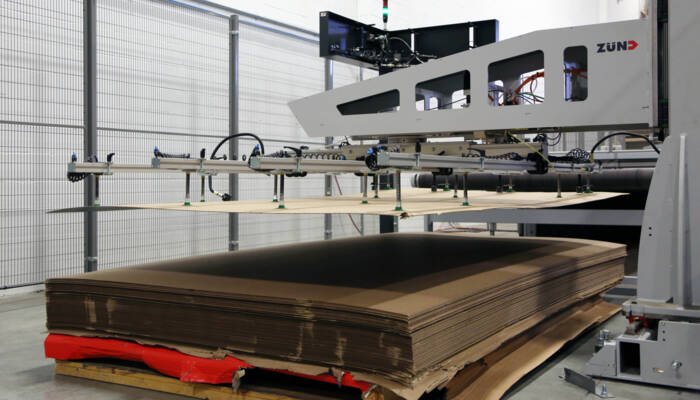

As for Zünd machinery itself, Townsend has nothing but praise for the craftsmanship, performance and reliability levels provided by the Zünd G3 L-3200 cutter – used for sampling, ultra short runs and redundancy and the Zünd D3-3200 cutter with a board handling system BHS150 used for short and medium production runs. Designed to accommodate a broad range of tooling modules, the Zünd G3 cutters are high-precision, high-performance flatbed digital cutting systems utilizing exceptionally sharp and durable knives, blades, routers, creasing wheels and other types of tooling to process materials up to 110-mm-thick – depending on beam height – with exceptional precision and virtually zero fiber loss or waste.

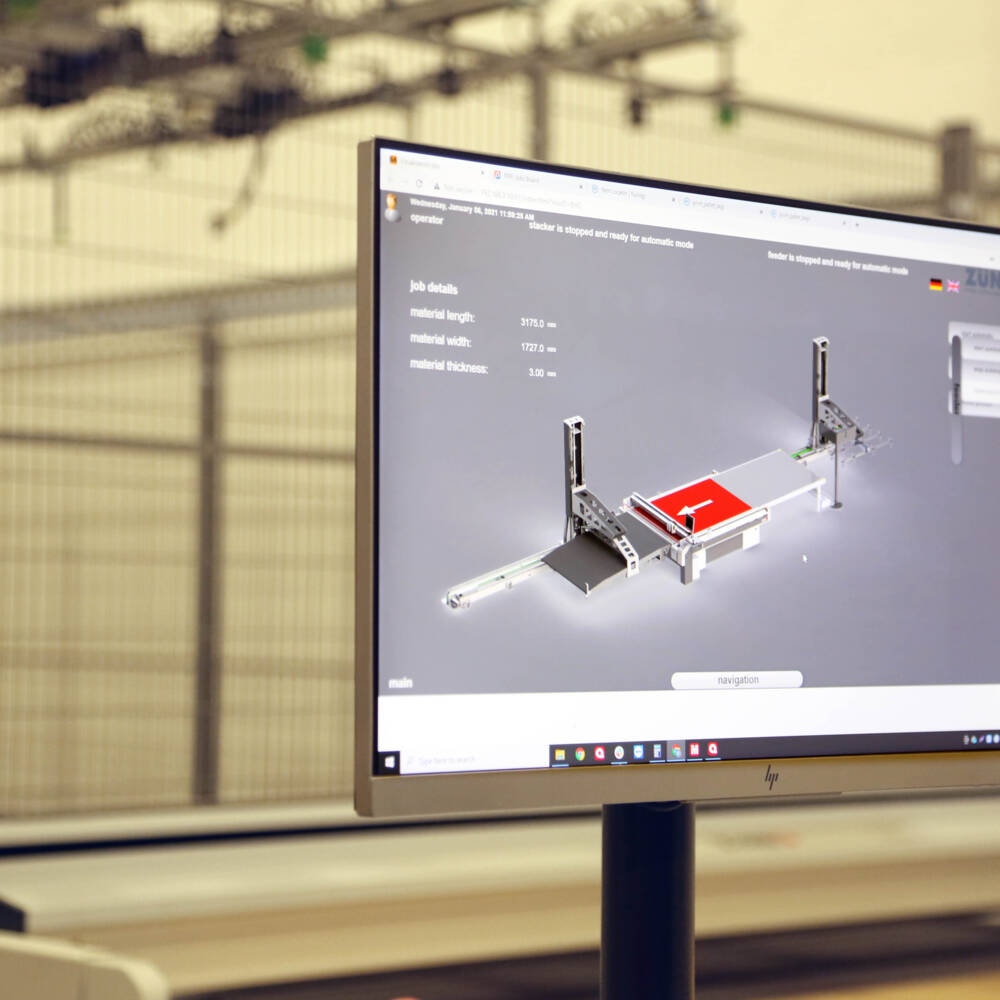

Using built-in vacuum generators to hold down the processed materials in place during processing, the modular Zünd D3 cutters are operated via Zund Cut Center software ZCC – containing an extensive material database with optimal cutting parameters for every material and every Zünd tool – that can be completely integrated into the digital workflow to support the end-user in every phase of job preparation. For its part, the Zünd D3 digital cutting system is equipped with two independently operating beams – each accommodating up to three different tools.

Equipped with a Zünd board handling system BHS150, the D3 cutters offers fully automated board load and unloading. “The dual-beam D3 Cutter doubles our cutting output,” Townsend notes, “while the G3 serves as a back-up unit – using the same tools to allow for redundancy if we need to boost production throughput.”

For Townsend, the Zund digital cutters are a perfect fit for the company’s digitalized workflow and relentless emphasis on waste minimization, thereby making its packaging products ever more sustainable. "With our digital lines we are able to not only create sheet combinations that reduce our waste on each layout, but also to pretty much eliminate all of our set-up waste for every process by running only exactly what is needed – creating close to zero obsolescence,” Townsend states. “The result is that we are able to take our sustainability measures much further by reducing the amount of waste throughout the entire system.”

All in all, Townsend says he expects PPP to benefit from the company’s proactive capital investment spending: “Our investment in digital technologies and automation and integration of processes will result in a long-lasting competitive advantage for us and our customers,” Townsend states. “I also believe that this strategy will prepare us to effectively compete in the future as we continue to attract and inspire a highly skilled and diverse workforce.” Says Townsend: “The display and packaging industry is in a state of continuous change due to the evolving retail formats, more demanding and tech-savvy shoppers, and the convergence of emerging technologies. “I also believe that most companies fail to understand the importance of their most critical resource – their employees,” he concludes. “Creating an environment that results in an inspired and creative workforce is essential to our success, which will be dictated by the practical identification and deployment of innovation across all our products and processes.”

Read the full article in the Jan/Feb 21 edition of Canadian Packaging Magazine.